Unlock and grow your business to the fullest potential by leveraging Wen Ken’s extensive manufacturing expertise, turning your product ideas into reality.

With a deep history rooted in innovating traditional medicine, Wen Ken has earned a reputation as a trusted leader in the healthcare and wellness sectors.

What began as a humble traditional medicine shop back in 1937 has evolved into a powerhouse of innovation and dependability.

In recent years, Wen Ken Group has boldly expanded into a medicine manufacturing company, offering their deep well of knowledge and high manufacturing standards to help other businesses transform their concepts into market-ready products.

Today, they are slowly improving to provide comprehensive solutions to guide companies in entering the healthcare market.

Wondering how a partnership with Wen Ken could be the main turning point for your business? Let’s explore how their contract manufacturing expertise can take your product to the heights of commercial success.

What is the Difference Between Contract Manufacturing and Subcontracting

Navigating the pharmaceutical industry can be challenging, especially when it comes deciding between the type of manufacturing that is suitable for your business.

There are two typically two types of manufacturing that are popular in the pharmaceutical industry:

| Contract Manufacturing | Subcontracting |

Both models allow businesses to outsource production, but they very much differ in scope and control.

Contract manufacturing involves a comprehensive partnership where the manufacturer handles everything from formulation to final packaging. In contrast, subcontracting usually focuses on specific tasks within the production process, offering less integration and control over the finished product.

For companies seeking end-to-end solutions and consistency, contract manufacturing is often the best choice.

Contract Manufacturing vs Private Label Brands

Speaking about pharmaceutical manufacturing, the distinction between contract manufacturing and private label brands is equally crucial. Contract manufacturing allows for full customization, ensuring your product aligns perfectly with your brand’s identity and needs.

Private label brands, however, are pre-formulated products that multiple companies can market under their own labels, limiting differentiation.

When bringing a product to market, businesses often face the decision between contract manufacturing and private label brands. While both options allow companies to outsource production, they differ significantly in scope, customization, legal considerations, target audience, and overall benefits.

1. Scope of Services

Contract manufacturing offers an all-inclusive solution, covering everything from product development to packaging. This allows businesses to create custom products that align with their brand. In contrast, private label brands provide pre-formulated products with limited customization, making them ideal for quick market entry without the need for product development.

2. Customization

Full customization is a significant advantage of contract manufacturing. It allows you to develop a product that meets your exact specifications, from ingredients to packaging. This is important if you are looking to create your own pharmaceutical formulation. .Private label products, however, offer minimal customization, usually limited to packaging and branding, making them suitable for businesses focused on speed rather than differentiation.

3. Legal Framework

Contract manufacturing involves a more complex legal framework due to intellectual property concerns, regulatory compliance, and quality agreements. This requires thorough legal review to protect your interests. On the other hand, private label brands involve a simpler legal process since compliance and standards are managed by the manufacturer, though with less control over quality and IP protection.

4. Target Audience

Contract manufacturing appeals to businesses seeking unique products for niche markets or those aiming to build long-term brand equity. Private label brands target businesses that prioritize quick market entry and lower costs, often suitable for retailers or e-commerce platforms.

5. Benefits of Contract Manufacturing

Contract manufacturing offers numerous benefits, including access to specialized expertise, high-quality materials, and scalable production. It also provides greater control over intellectual property, enabling innovation and flexibility as market trends evolve.

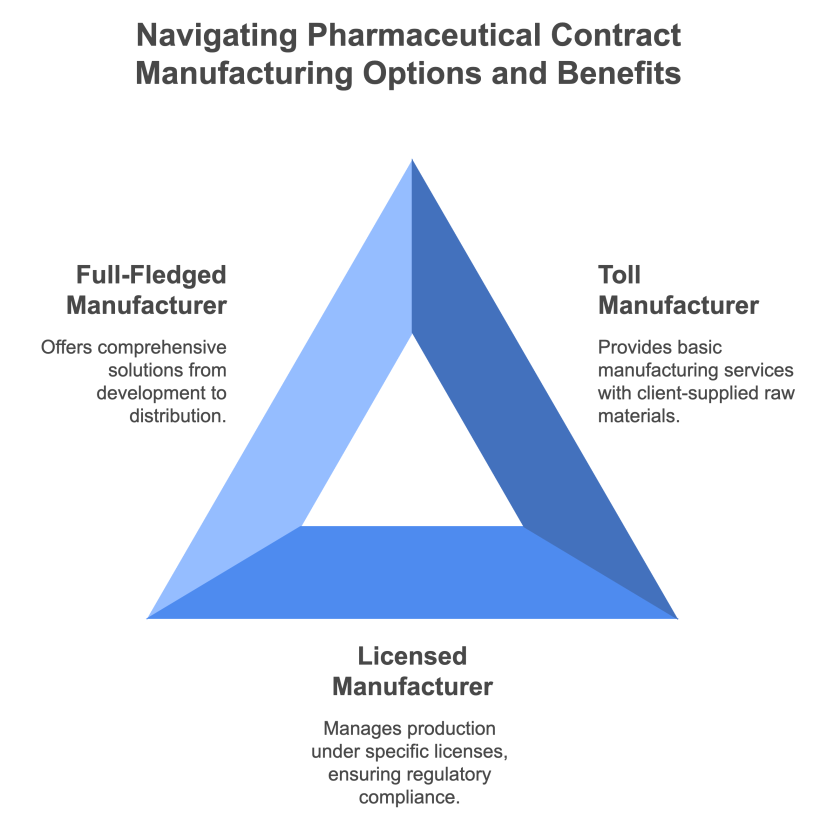

Types of Contract Manufacturing

Pharmaceutical contract manufacturing can be categorized into three main types:

Toll Manufacturer: Provides basic manufacturing services where the client supplies raw materials, and the manufacturer processes them into the final product. This option offers flexibility but requires the client to manage sourcing and logistics.

Licensed Manufacturer: Handles production under specific licenses, ensuring all processes comply with regulatory standards. The client benefits from the manufacturer’s expertise in navigating complex legal and compliance requirements.

Full-Fledged Manufacturer: Offers a complete end-to-end solution, from product development and raw material sourcing to manufacturing, packaging, and distribution. This type is ideal for companies seeking a seamless, all-in-one service with minimal client involvement.

Each type serves different needs, allowing businesses to choose the model that best fits their resources and goals.

How to Select the Right Contract Manufacturer

Choosing the right contract manufacturer is a critical decision that can make or break your business’s success in the market. Start by evaluating the manufacturer’s experience and expertise in your industry. A seasoned partner will understand the unique challenges and regulatory requirements associated specifically with your product development.

Quality assurance is another key factor to ensure that the manufacturer follows stringent quality control processes and holds relevant certifications. Scalability is equally important as your partner should be able to grow with you, adapting to your needs and also the increased demand without compromising on quality.

Finally, consider their ethical practices and sustainability initiatives, as people are getting more conscious of the practices that are aligned with the UN’s Sustainable Development Goals. In today’s market, aligning with a manufacturer that prioritizes responsible practices will make a big impact on your brand’s reputation and appeal.

Wen Ken’s Contract Manufacturing Services

Wen Ken stands out as a leading contract manufacturer, offering a broad spectrum of services tailored to meet diverse business needs. Their end-to-end solutions cover every aspect of production, from research and development to final packaging. Whether you’re a startup looking to launch your first product or an established company seeking to expand, Wen Ken’s comprehensive services provide the support you need at every stage.

Advantages of Partnering with Wen Ken

Partnering with Wen Ken comes with several advantages, First and foremost is their decades of expertise in the pharmaceutical and healthcare industries, ensuring that your product benefits from industry-leading knowledge and practices. Additionally, having local state-of-the-art facilities ensures also that your production is of a higher standard and reachable. Wen Ken also offers flexible production capabilities, allowing you to scale operations as your business grows.

Wen Ken’s Core Competencies

Wen Ken’s core competencies lie in their ability to combine innovation with reliability. As a trusted halal OEM manufacturer, they bring a unique blend of expertise in product formulation and advanced manufacturing technologies to the table. This ensures that every product not only meets stringent quality criteria but also aligns with halal standards, catering to a growing market demand.

Furthermore, Wen Ken’s deep understanding of regulatory requirements across different markets makes them a trusted partner for businesses aiming to expand internationally throughout SEA. Their commitment to continuous improvement means they are always ahead of the curve, offering cutting-edge solutions that keep your products competitive.

Sustainability and Ethical Practices

Wen Ken places a strong emphasis on sustainability and ethical practices. They are committed to reducing their environmental footprint by implementing green manufacturing processes and sourcing materials responsibly. Moreover, Wen Ken adheres to strict ethical guidelines, ensuring that all operations are conducted with integrity and respect for human rights. By choosing Wen Ken, you align your brand with a partner that values both quality and responsibility—a combination that resonates well with today’s socially-conscious consumers.

Ready to Start Your Brand? Partner with Wen Ken Today!

In today’s competitive market, choosing the right manufacturing partner can be the difference between success and mediocrity. With Wen Ken’s decades of experience, cutting-edge technology, and commitment to quality and sustainability, your products are in the best possible hands.

Whether you’re looking to create a unique, customized product or need a reliable halal OEM manufacturer to meet your market’s demands, Wen Ken has the expertise and resources to bring your vision to life.

Don’t leave your business growth to chance, take the next step towards innovation and excellence by partnering with a contract manufacturer that truly understands your needs. Reach out to us today for a quick consultation today, and let us take care and build your products.